Photovoltaic greenhouses: the advantages of an eco-friendly solution

02/05/2019

The new Combilux metal greenhouse for Margheriti Plants: features and advantages

05/06/2019The first semi-closed Venlo greenhouse in Italy:

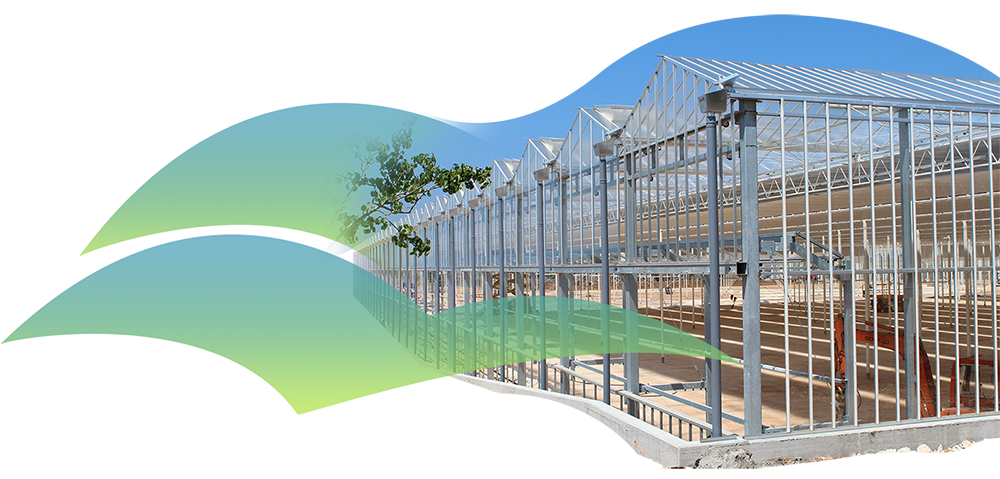

This is the first project of this kind in Italy and it represents a real turning point in the greenhouses field. It is the first semi-closed Venlo greenhouse in Italy and is designed by Artigianfer for the Fratelli Lapietra farm, with the aim of making production and energy consumption more efficient.

Among the glass greenhouses, the Venlo one is today the most widely used but a semi-closed model has new advantages and special features.

Venlo greenhouses more and more innovative

Artigianfer, for decades engaged in the design and construction of any type of turnkey greenhouse, is specialized in the production of glass greenhouses: we can consider it the top of the range of the company. Versatile, robust and suitable for any type of plant and crop, they are made to measure to meet the specific needs of each customer.

The Venlo greenhouses, among the glass models, are the most requested and the most widely used. This is the reason why Artigianfer has dedicated a lot of time and resources to the development of a model that meets the needs of modern protected crops: today, Artigianfer Venlo greenhouses are produced with an aluminium kit of its own conception and are suitable for the cultivation of flowers and vegetables in all seasons and at any latitude.

In addition, it is a semi-closed greenhouse, which is especially important from an energy point of view: this type of greenhouse, in fact, allows the accumulation of excess summer radiation in the groundwater and then use it in winter, through heat pumps that heat and dehumidify the environment. This increases the concentration of CO2 and prevents the entry of insects and pathogens. Moreover, the climate inside the greenhouse is always controlled by the active air exchange: the air is treated to control humidity, temperature and CO2 levels; these factors are all strictly controlled.

The first semi-closed Venlo greenhouse in Italy

In Northern Europe, especially in the Netherlands, this is a model already widespread in horticulture, but in Italy a semi-closed Venlo greenhouse has never been built. What Artigianfer is developing for Fratelli Lapietra, an agricultural company specialized in the cultivation of vegetables, is the first project that will be carried out in our country: an agricultural semi-closed Venlo greenhouse will be a real turning point in the greenhouse sector.

The fact that it is a semi-closed model, has completely new advantages over the classic Venlo greenhouses and meets the needs of protected crops.

Technical features and peculiarities

The semi-closed Venlo greenhouse made for Fratelli Lapietra is a metal greenhouse with horizontal beam, two combs and a span of 5 m. The eave height is 7 m, including a 30 cm perimeter wall, and the prefabricated structure is made of steel and aluminium. There are two roofs with a nave of 4.80 m each, with a slope of about 22 ° and aluminum structure. On the pitched roof there are openings, equipped with hinges, blocks and gaskets to prevent slippage, and special anti-insect nets. The particular system of openings is divided into 3 independent sectors to leave the maximum freedom of management to the farmers and ensure the least possible loss of light.

The structure is divided into two parts: the front of greenhouse and the farming greenhouse. The front of the greenhouse is covered with sandwich panel with external coating in Plastisol, while the farming greenhouse is covered with glass with diffused light.

Among the peculiarities of the first semi-closed Venlo greenhouse in Italy there will be the Air Control Corridor that will allow you to air, heat and cool the greenhouse for total control of the climate, and the shading and insulation system.